In a world where creativity knows no bounds, Odyssey 3D printing is the rocket fuel every innovator needs. Imagine turning your wildest ideas into tangible reality faster than you can say “layer by layer.” Whether it’s a quirky desk toy or a prototype that could change the game, this technology makes it all possible.

Table of Contents

ToggleOverview of Odyssey 3D Printing

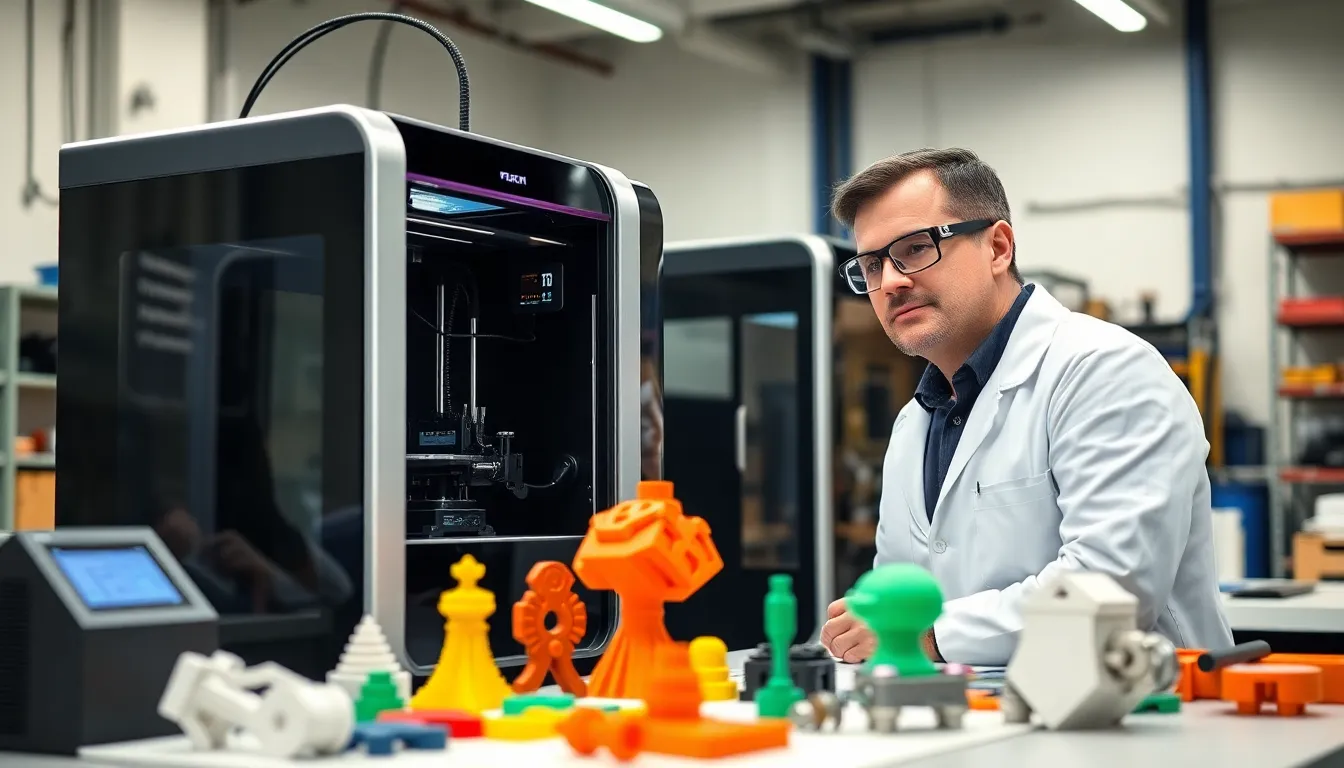

Odyssey 3D printing stands at the forefront of modern manufacturing technologies. This innovative approach enables creators to transform concepts into tangible products rapidly. Versatility remains a key feature; users can design and produce a wide array of items, from functional prototypes to intricate decorative objects.

The process utilizes advanced printing technologies, enhancing precision in every layer. Materials used in Odyssey 3D printing include various plastics and metals, allowing for diverse applications across industries. For instance, architects can produce intricate scale models while engineers develop complex mechanical parts.

Creativity thrives with the Odyssey system, as it supports different printing techniques such as FDM (Fused Deposition Modeling) and SLA (Stereolithography). Each method offers unique advantages, optimizing the workflow depending on specific project requirements. Therefore, users can select the most suitable technique based on material compatibility and finishing quality.

Efficiency and cost-effectiveness play significant roles in adopting Odyssey 3D printing. By shortening production times, organizations can respond quickly to market demands. Lower material waste also contributes to an environmentally friendly manufacturing process.

Moreover, the technology encourages collaboration among teams, as iterative designs become easy to modify and prototype in real-time. This flexibility empowers designers and engineers to explore multiple versions while minimizing delays in development cycles.

Building a robust prototype with Odyssey 3D printing results in improved product quality and performance. Customization options enable businesses to cater to specific customer needs without extensive retooling or additional costs.

Key Features of Odyssey 3D Printing

Odyssey 3D printing offers various key features that enhance its usability and effectiveness across different projects. These aspects include build quality, design, and the advanced printing technologies employed in the process.

Build Quality and Design

Build quality significantly impacts the end product. Odyssey 3D printers utilize robust materials that ensure durability and reliability in printed items. Designed for versatility, these printers can create intricate shapes and details, reflecting the user’s vision accurately. Additionally, the printers’ construction allows for stable operations, reducing potential errors during the printing process. Each device incorporates advanced mechanisms that enhance structural integrity while maintaining a compact design, enabling use in various environments.

Printing Technology

Odyssey 3D printing employs cutting-edge technologies to optimize output. Fused Deposition Modeling (FDM) and Stereolithography (SLA) are key techniques. FDM provides affordability and quick turnaround, ideal for rapid prototyping. Meanwhile, SLA excels in precision, producing high-resolution models with smooth surfaces. Each technology addresses diverse project needs, whether for detailed artistic projects or industrial applications. This adaptability makes Odyssey 3D printing an essential solution for creators across multiple fields, from engineering to architecture.

Applications of Odyssey 3D Printing

Odyssey 3D printing finds extensive applications across various industries, showcasing its transformative capabilities.

Industry Use Cases

Manufacturing sectors utilize Odyssey 3D printing for multiple purposes. Aerospace companies make lightweight components that withstand high stress. Medical professionals design custom prosthetics tailored to patient needs. Automotive manufacturers create intricate parts for faster prototyping and reduced costs. Consumer products leverage this technology to innovate and respond to market trends quickly. Architecture benefits from accurate scale models, aiding in presentations and client approvals.

Prototyping and Manufacturing

Prototyping remains a critical area for Odyssey 3D printing. Engineers create functional prototypes that test designs before mass production. Development teams can modify designs rapidly, allowing for iterative improvements. Speed plays an essential role in bringing products to market faster. Manufacturing processes improve, reducing time and costs associated with traditional methods. Customization of parts enables businesses to meet specific demands without extensive retooling. Overall, this versatility leads to higher quality outcomes and enhanced product performance.

Benefits of Using Odyssey 3D Printing

Odyssey 3D printing offers significant advantages in various industries. Efficiency stands out as one of its main benefits. Reduced production times translate to faster turnaround, allowing companies to bring products to market more quickly.

Cost-effectiveness also contributes to its appeal. Lower material waste and fewer resources needed for manufacturing result in substantial savings for businesses. Creativity thrives in this environment as various printing techniques enable users to explore innovative designs without limits.

Collaboration is another advantage. Teams can easily modify designs in real-time, enhancing communication and fostering iterative prototyping. This approach minimizes delays throughout development cycles, streamlining project progression.

Quality of prototypes improves significantly with Odyssey 3D printing. The technology supports durable materials that offer reliability, which ensures the final product matches initial visions. Intricate shapes and details manifest accurately, meeting the requirements of customers.

Versatility across applications enhances its importance in manufacturing and other sectors. Architects create complex scale models while medical professionals design personalized prosthetics. Aerospace companies produce lightweight components, showcasing how Odyssey 3D printing caters to a wide range of needs.

Supporting various materials further increases adaptability. Odyssey 3D printing works with plastics and metals, allowing users to select the best fit for their projects. This flexibility ensures that specific customer requests receive the attention they deserve.

Odyssey 3D printing empowers innovation through efficiency, cost savings, collaboration, quality, versatility, and material support. These benefits position it as a pivotal tool in the modern manufacturing landscape.

Odyssey 3D printing represents a significant leap in manufacturing capabilities. Its unique blend of efficiency and versatility empowers creators to explore innovative designs and produce high-quality prototypes. This technology not only accelerates production times but also minimizes waste, making it a sustainable choice for various industries.

With its advanced printing techniques and material support, Odyssey 3D printing is redefining how products are developed. From intricate architectural models to custom medical devices, the applications are virtually limitless. As businesses continue to embrace this cutting-edge technology, they’ll find themselves better equipped to meet the demands of an ever-evolving market.