In the world of 3D printing, achieving that flawless finish can feel like a high-stakes game of hide and seek. Enter ironing, the unsung hero of print perfection. Imagine a magical process that smooths out those pesky layer lines, transforming your rough drafts into sleek masterpieces. It’s like giving your 3D prints a spa day—who wouldn’t want that?

Table of Contents

ToggleWhat Is Ironing in 3D Printing

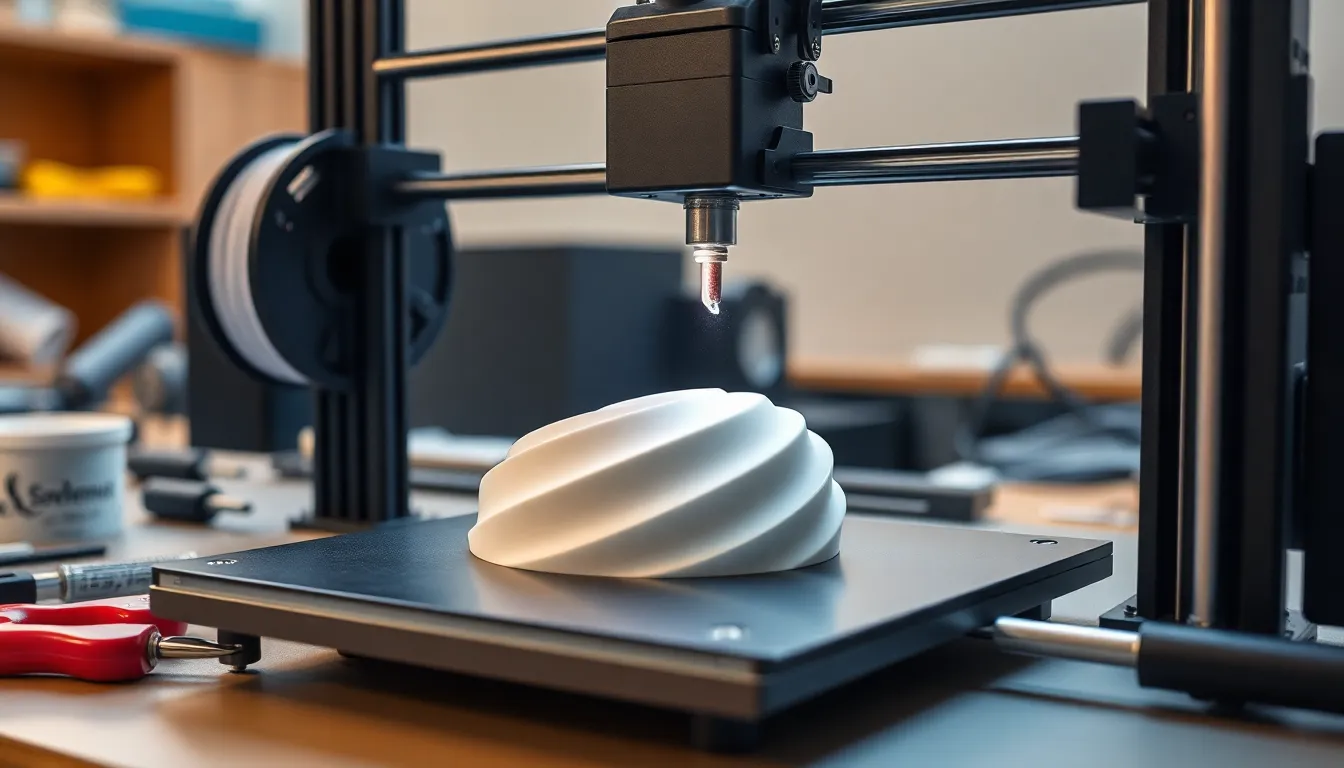

Ironing in 3D printing refers to a post-processing technique that enhances print surface quality. This method targets layer lines on a printed object, producing a smoother finish. During ironing, the printer makes additional passes over the existing surface, applying just enough heat to slightly melt the filament’s top layer.

This process significantly improves the aesthetics of prints, especially for intricate models. When employed, ironing reduces the visibility of layer lines without the need for sanding or additional manual finishing work. It achieves optimal results when used on flat or horizontal surfaces, where imperfections are most apparent.

Commonly, slicing software includes an ironing feature, allowing users to toggle it on or off in the settings. Each layer receives a light skim, which fills in gaps and evens out the surface. Users can control parameters like speed and temperature to refine the ironing effect, tailoring results to specific materials.

Effective use of ironing has various advantages. It enhances print quality, reduces the need for further finishing, and minimizes manual labor. Moreover, it optimizes the overall appearance of 3D prints, making them visually appealing for display or use.

Many materials respond well to ironing, but PLA often achieves the best results due to its lower melting temperature. It’s crucial to monitor the process, as excessive heat can lead to unwanted deformation. Refining the ironing settings based on the material and design is essential for achieving the desired finish.

Benefits of Ironing in 3D Printing

Ironing significantly enhances the quality of 3D prints, offering numerous benefits for users.

Improved Surface Finish

Smoother surfaces result from the ironing process, which targets unsightly layer lines. The printer’s extra passes slightly melt the top layer, creating a polished finish. Many users notice an immediate improvement in their prints’ tactile quality and visual appeal. Ironing works exceptionally well on flat or horizontal areas, where imperfections are most noticeable. Achieving a refined surface finish is accessible through simple adjustments in slicing software. Customizable parameters allow users to control speed and temperature to match different materials. Overall, this effective technique streamlines the finishing process and often eliminates the need for additional post-processing steps.

Enhanced Aesthetic Appeal

Visually, ironing transforms 3D prints into more attractive objects. The technique removes layer lines that detract from the overall look, allowing intricate designs to shine. Custom projects benefit especially, as the smooth surface emphasizes fine details and craftsmanship. Enhanced aesthetic appeal plays a critical role in creating display-worthy pieces. Even practical items gain a polished edge, making them more appealing for users and potential customers. Crafting an eye-catching product remains crucial in the competitive world of 3D printing. When users present their work without visible flaws, it captures attention and elevates their designs to a professional level.

How Ironing Works in 3D Printing

Ironing improves surface quality in 3D prints by targeting layer lines. This process involves the printer making additional passes over the surface, applying just enough heat to slightly melt the top filament layer. Such adjustments lead to a smoother overall finish without requiring manual sanding.

The Process Explained

During ironing, the extruder glides over specific areas of the print. It’s designed to operate at a reduced extrusion rate, allowing for precise control over the filament flow. Layer lines become less visible as the extruder effectively smooths the surface. The heat application melts only the uppermost layer, creating a seamless appearance. Flat and horizontal surfaces receive the most significant benefit from this technique, making it ideal for achieving visually appealing outcomes.

Key Parameters for Effective Ironing

Effective ironing requires careful adjustment of specific settings. Temperature settings play a vital role, as excessive heat can lead to deformation of the print. Speed settings impact the duration of heat exposure on the surface. Users should also consider the material type, with PLA often providing optimal results due to its lower melting point. Slicing software usually includes parameters that can be customized, offering flexibility for various printing materials. Proper calibration ensures a professional-looking finish that enhances the final product.

Common Applications of Ironing

Ironing finds application in both prototyping and final product production, enhancing the overall quality of 3D prints.

Use in Prototyping

Prototyping benefits significantly from ironing techniques. Designers often use it to create smoother surface finishes, which visually communicate design intent more effectively. Accurate surface quality allows for better evaluation of form, fit, and function during the prototyping phase. This enhancement reduces the need for additional post-processing steps, saving time and resources. Iterative design processes become more efficient, as refined prototypes demonstrate features clearly. Users can also present prototypes with a more professional appearance to stakeholders and clients, facilitating better feedback during development.

Use in Final Products

Ironing enhances the visual appeal of final products. The improved surface finish elevates aesthetic quality, attracting customers and standing out in competitive markets. Consumers often prefer items with seamless finishes, as they suggest higher quality and craftsmanship. Ironing works particularly well on products meant for display, such as decorative pieces or custom gifts. Many manufacturers utilize this technique to ensure their products meet high standards before reaching the market. Adjusting parameters like speed and temperature can tailor the ironing effect to specific materials, maximizing the benefits for each final piece.

Ironing in 3D printing is a game-changer for enhancing surface quality. By effectively smoothing out imperfections it transforms prints into visually striking pieces. This technique not only improves aesthetics but also reduces the need for extensive post-processing, saving time and effort.

With careful adjustments to speed and temperature settings users can achieve professional finishes that elevate their designs. Whether for prototypes or final products ironing ensures that each piece stands out in a competitive market. As 3D printing continues to evolve ironing will remain an essential tool for creators aiming for perfection in their work.